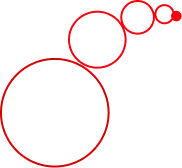

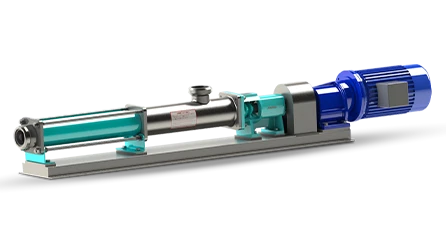

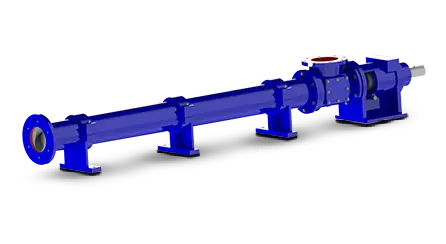

FSP - Series Industrial Pumps

These pumps are designed for rigid construction of cast iron with alloy steel / Stainless steel rotating parts.

For corrosive Chemical applications, the pumps are of complete stainless steel construction. Rotor & Stator material combinations are available for the pumping of high-abrasive or Corrosive fluids. The suction & delivery connections are. available for ISO, BS/DIN, or other equivalent connections are also provided to suit the specific requirements.

Specification

- Flow Rate: Up to 500 M3 / HR

- Pressure: 6 , 12 , 24 , 36 , 48 (BAR)

Material of Construction

- Bearing Housing: CI IS 210 FG 260

- Pump Housing: CI IS 210 FG 260, CF 8, CF 8 M

- Rotor: Alloy Steel, Tool Steel, AISI 304, AISI 316, Hard Chrome Plated

- Other Rotating Parts: Alloy Steel, Tool Steel, AISI 304, AISI 316

- Bonded Stator: Natural, NBR, HNBR, EPDM, Hypalone, Newoprene, Silicon, Viton etc

- Alkaline Slurry

- Bentonite Slurry

- Black Liquir

- Casein Slurry

- Ceramic Slurry

- Coating Mix

- Detergent Slurry

- De - Watered Sludge

- Electro Plating

- Coating Mix

- Detergent Slurry

- De-Watered Sludge

- Electro Plating Solution Slurry

- Emulsion

- Ferrite Slurry

- Fuel Oil Sludge

- Glue

- Grout Mix

- Gum Sludge

- Industrial Waste

- Latex

- Lube Oil

- Magma

- Massecute

- Molasses

- Oil Sludge

- Paint

- Varnish

- Paper Stock

- Paper & Pulp

- Printing Ink

- Sewage Sludge

- Soap Stock

- Sodium Silicate

- Sulphited Sugar Juice

- Spent Wash

- Varnish

- Vegetable Oil

- Viscose

- Water To Thickened Sludge

- Petroleum Jelly Etc..

Other Products

FSP - Series Industrial Pumps

These pumps are designed for rigid construction of cast iron with alloy steel / Stainless steel rotating parts. For corrosive Chemical applications, the pumps are of complete stainless steel construction.

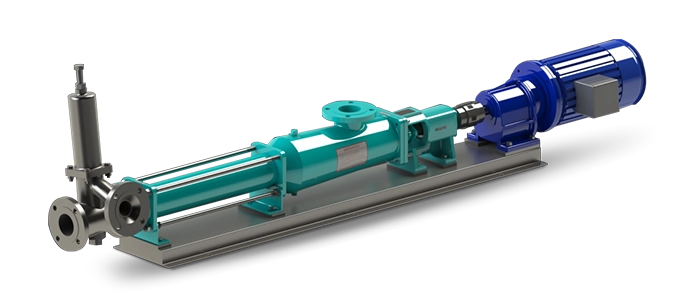

FSS - Series Hygine Sanitary Design Pumps

These pumps are designed for hygiene applications. All the material parts in contact with the fluids are in smooth-finished stainless steel. The stators are of NON- NON-CONTAMINATED FOOD GRADE elastomers viz NBR, EPDM, SILICON & VITON.

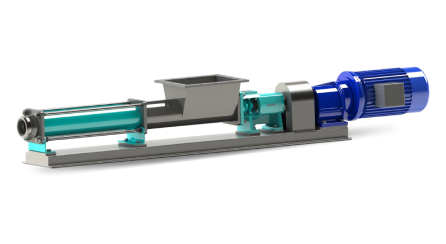

FSH - Series Hygine Sanitary Hopper Pumps

These pumps are constructed with STAINLESS steel housing (wide throat design) for high viscous & fiberous fluid transferring applications. The hopper type suction allows gravity flow of plastico-viscous material on to augur cum coupling rod pushes viscous substances in to pumping cavity.

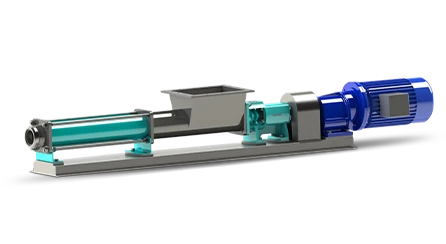

FSW - Series Industrial Hopper Pump

These pumps are constructed with a MILD STEEL wide-mouth hopper, and all the rotating parts are in alloy/ tool steel. For corrosive chemical transfer, the pumps are in complete Stainless Steel construction.

FSV - Series Vertical Pumps

These are compact and sleeve design vertical pumps driven by flanged-mounted prime movers for emptying the barrels.Various options in the joints, such as double-sealed bush/ pin.

FL Frame Pumps

These pumps are identical to the L-Frame Progressive Cavity pumps and are available for a wide variety of applications. These pumps are offered with many different types of shaft sealing arrangements.

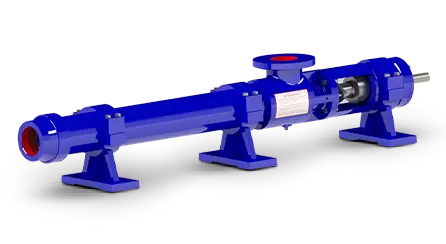

FM Series Pumps

These pumps are very robustly designed for heavy-duty applications. These pumps are equipped with a CI bearing frame with a large bearing to transmit a heavy workload and easily provide a long service life.