FSV - Series Vertical Pumps

These are compact and sleeve design vertical pumps driven by flanged-mounted prime movers for emptying the barrels.

Various options in the joints, such as double-sealed bush/ pin. Open bush/pin, etc are available. Delivery options with flange, SMS, or suitable connections are available. Mild Steel or Stainless Steel material constructions with internal rotating parts to suit any condition. Shaft sealing is done by soft gland packing or mechanical Seal.

Specification

- Flow Rate: Up to 500 M3 / HR

- Pressure: 6, 12,24,KG/ CM 2 (BAR)

Material of Construction

- Bracket: WCB/CS, MS, AISI 304, AISI 316, Fabricated

- Pump Housing: MS, AISI 304, AISI 316 Seamless

- Rotor: Alloy Steel, Tool Steel, AISI 304 HCP, AISI 316 Un Plated, Plated

- Rotating Parts: Alloys Steel, Tool Steel , AISI 304/316

- Bonded Stator: NBR, HNBR, EPDM, Hypalone, Neoprene, Silicon, Viton etc

- Fruit Concentrate

- Paste

- Butter

- Cake – Mix

- Chocolate Mix

- Coco Paste & Vegetable Mash

- Ghee

- Grease

- Asbestos Slurry

- Grout MI X

- Explosive Slurry

- High Consistency Paper Pulp

- Lecithin

- Honey

- Tooth Paste

- Malt

- Minced Meat

- Mash Grapes

- Oil Paste

- Paint Pre–Mix

- Grape Mash

- Pickle Mix

- Pigmented Varnish

- Putty

- Starch Slurry

- Liquid Glucose

- Thick Coal Slurry

- Ink

- Undiluted SLUDGE

- Yoghurt Etc.

Other Products

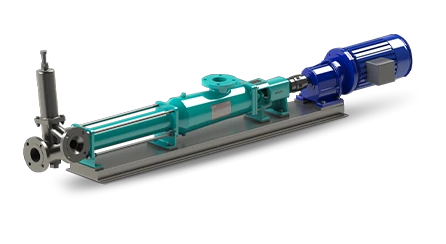

FSP - Series Industrial Pumps

These pumps are designed for rigid construction of cast iron with alloy steel / Stainless steel rotating parts. For corrosive Chemical applications, the pumps are of complete stainless steel construction.

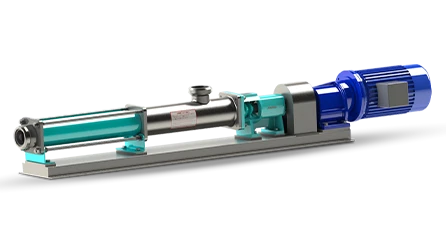

FSS - Series Hygine Sanitary Design Pumps

These pumps are designed for hygiene applications. All the material parts in contact with the fluids are in smooth-finished stainless steel. The stators are of NON- NON-CONTAMINATED FOOD GRADE elastomers viz NBR, EPDM, SILICON & VITON.

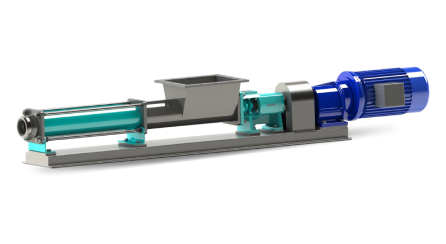

FSH - Series Hygine Sanitary Hopper Pumps

These pumps are constructed with STAINLESS steel housing (wide throat design) for high viscous & fiberous fluid transferring applications. The hopper type suction allows gravity flow of plastico-viscous material on to augur cum coupling rod pushes viscous substances in to pumping cavity.

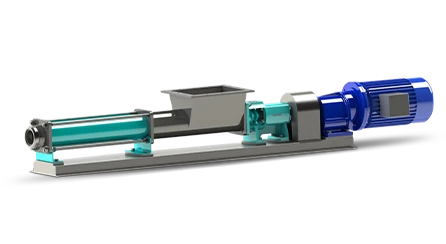

FSW - Series Industrial Hopper Pump

These pumps are constructed with a MILD STEEL wide-mouth hopper, and all the rotating parts are in alloy/ tool steel. For corrosive chemical transfer, the pumps are in complete Stainless Steel construction.

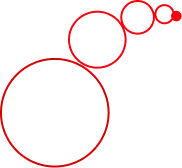

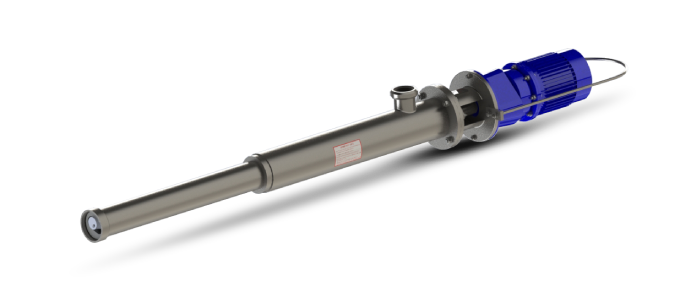

FSV - Series Vertical Pumps

These are compact and sleeve design vertical pumps driven by flanged-mounted prime movers for emptying the barrels.Various options in the joints, such as double-sealed bush/ pin.

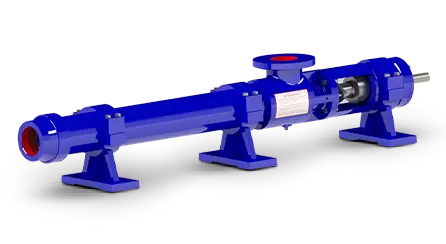

FL Frame Pumps

These pumps are identical to the L-Frame Progressive Cavity pumps and are available for a wide variety of applications. These pumps are offered with many different types of shaft sealing arrangements.

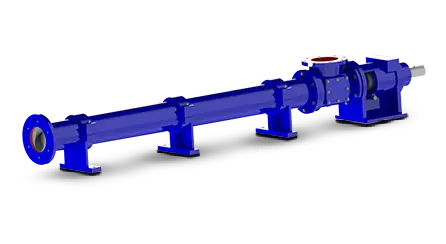

FM Series Pumps

These pumps are very robustly designed for heavy-duty applications. These pumps are equipped with a CI bearing frame with a large bearing to transmit a heavy workload and easily provide a long service life.